Business Overview

Dexon Technology PLC

Dexon Technology PLC provides inspection services for the inspection of structures and production equipment throughout a variety of industries. Ensuring the safe and profitable operation of assets. A team of more than 70 experts from Dexon’s research development and engineering department lead innovation in the industry through the development of new inspection technology and techniques.

For over 26 years Dexon Technology PLC has pioneered many of the Conventional and Advanced Non-Destructive Testing and In-line Inspection methods utilized throughout Southeast Asia today. Serving the petroleum, petrochemical, and power generation industries worldwide.

Dexon has been responsible for pioneering internationally certified rope access training courses from the Industrial Rope Access Trade Association (IRATA) in the United Kingdom. Opening an internationally accredited rope access training center for the training of inspection personnel throughout Southeast Asia to meet the growing need for international certification.

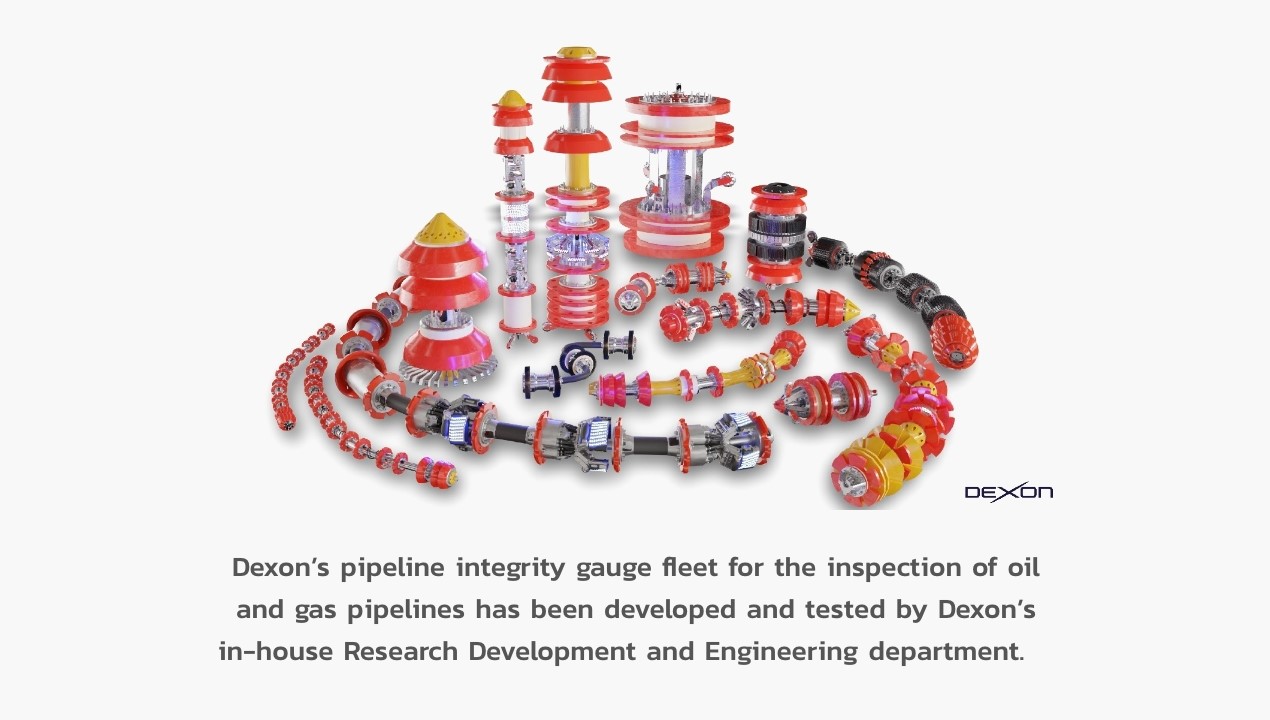

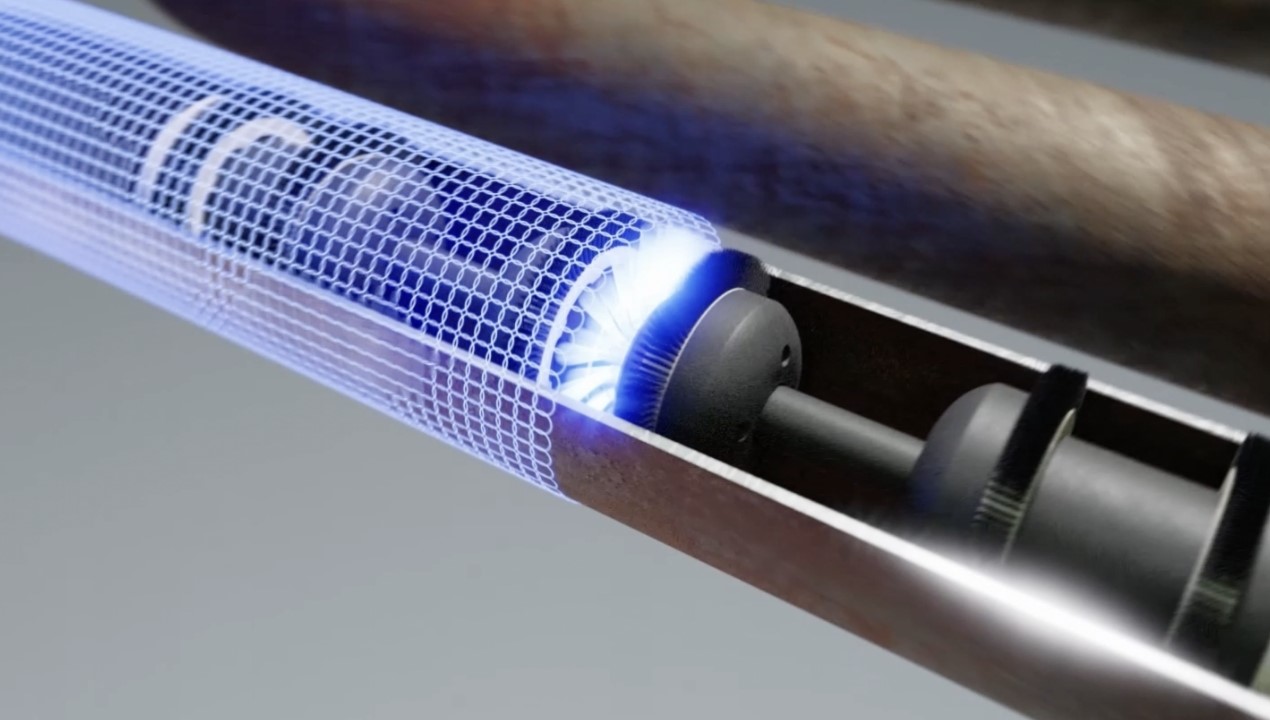

In 1999 Dexon launched a program for the development of ultrasonic in-line inspection devices to measure the wall thickness of oil and gas pipelines in the gulf of Thailand, in collaboration with PTT Exploration and Production Public Company Limited and Total Exploration and Production. It was this collaboration that led to the development of Dexon’s R&D department.

World map showing the countries that Dexon has performed inspection services to date.

World map showing the countries that Dexon has performed inspection services to date.

Dexon Technology is one of the leading providers of Advanced and Conventional Non-Destructive Testing throughout Asia. Offering the following internationally certified inspection standards.

Dexon’s goal is to become the world’s leading supplier of Advanced Non-Destructive Testing and In-Line Inspection services globally. Building on an extensive 26 years of inspection experience with more than 340 employees globally. Continuing to meet the ever-changing needs of the energy industry as the world moves away from fossil fuels and towards clean and renewable energy such as hydrogen, solar, and wind power.

Dexon Technology’s expansion plan involves establishing offices in Europe and the United States to better serve international In-line Inspection markets increasing market share. With the offering of new In-line Inspection technology including the UT-CS crack detection and sizing hawk ILI system, and the Dexon Scorpion fleet for the inspection of furnaces and fired heaters.